- Home

- Business Information

BUSINESS INFORMATION

OUR BUSINESS

Items We Handle

Our company mainly handles primary and secondary alloy ingots, and pellets for deoxidizing molten iron.

・Aluminum ingots

・Aluminum ingots for electrical use

・Aluminum alloy ingots for high-electrical-resistance rotors

・Aluminum alloy ingots for self-coloring on anodizing process

・Aluminum alloy ingots for gravity casiting

・Aluminum alloy ingots for high pressure die casting

・Various types of master alloys (Al-Si-based, etc.)

・Aluminum pellets for deoxidizing molten iron

・Reminted ingots of aluminum and aluminum alloys

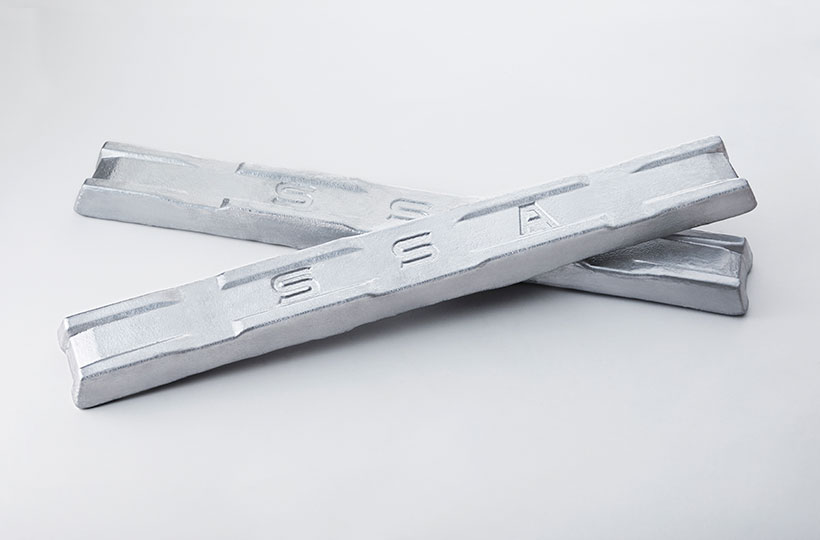

Primary alloy ingots

Aluminum is produced by electrolytically smelting aluminum oxide powders called alumina extracted from a reddish-brown ore called bauxite. Alloys made from this kind of pure aluminum, which is very low in impurities, are called primary alloys.

Primary alloy ingots are high-quality materials that are strictly controlled to ensure they are low in impurities and have stable compositions.

Secondary alloy ingots

Secondary alloys are mainly made by recycling scrap. Since scrap from various kinds of alloy products is used as the raw material, secondary alloy ingots contain various impurities, such as iron. We manufacture secondary alloy ingots under the same level of quality control as primary ones. Our secondary alloy ingots are mainly used in Japan.

Pellets for deoxidizing molten iron

These pellets are used by steel manufacturers as additives to remove oxygen in molten iron. We provide pellets in a variety of forms so we can meet every customer's needs. They are environmentally-friendly products made from scrap materials, and support Japanese "monozukuri."

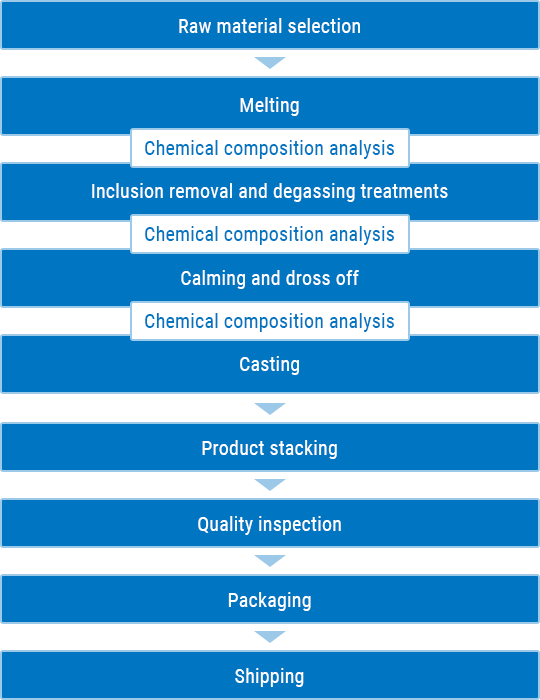

Manufacturing flow chart